3D laser printing has entered the norm with everyone from understudies, to trained professionals, to privately owned businesses jumping aboard with the 3D laser printing transitory trend. Despite the way that for countless us the advancement is decently new, 3D laser printing or added substance creating, as it is moreover known, began during the 70s and 80s, with the undertakings of scientists and graduate understudies to sort out some way to even more gainfully and monetarily make stock from a more minor point of view. The middle gathering measures – anticipating/molding, outlining, joining and machining – have not been displaced by 3D printing, as one may figure, yet have basically been scaled down through the adaption of new techniques in amassing. New strategies for solid showing have allowed researchers to make a translation of 3-D computations into mathematical terms, which accordingly enabled them to transform into the headings for gear control systems.

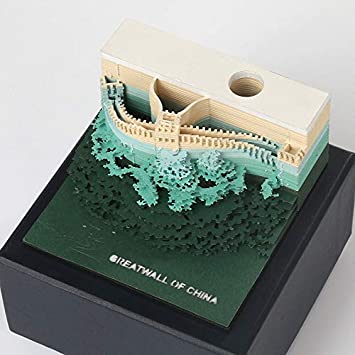

As added substance delivering has created, taking on new cycles and advances in solid amassing, the development has reached out to supporting quick creation from automated models or formats and an extent of estimations that beats the capacities of various procedures. The a great deal of the additional substance manufacturing methods that make up the foundations of the advancement were made and secured during the 80s. To all the more promptly appreciate 3d printing today, we should review a bit of the parts that incited making it and try on Omoshiroi Block Shape. In any case, added substance manufacturing, fundamentally, is a pattern of making something three dimensional by really layering materials upon each other after a high level arrangement or format. What follows is a short framework of a bit of the principal 3D printing or added substance creating procedures and cycles.

3D memo pad, on occasion called tank photograph polymerization, is an additional substance creating measure that uses saps and lasers to amass 3D items. Specific laser sinteringSLS, in any case called powder bed mix, uses a PC controlled laser for instance, a fixed off CO2 laser to specificallysinter, or interlace, cross-spaces of powder into a solid. Sheet cover, in any case called overlaid object creating, is the path toward cutting a shaky piece of paper, plastic or metal into an ideal shape with a laser, repeating this and holding each layer upon the previous one. In a progressing article of Phys.org, Steve McKnight, top of the NSF Division of Civil, Mechanical, and Manufacturing Innovation, was referred to as saying, to comprehend the full assurance of added substance manufacturing, experts should discover better ways to deal with accelerate, lower costs, improve consistency and make and qualify novel materials for a wide scope of uses. It will take the imagination of subject matter experts, understudies and makers.